Industrial equipment downtime costs operations thousands of dollars every hour production stops. When powertrain systems fail, entire projects grind to a halt, deadlines slip, and emergency repairs drain budgets. The difference between minor maintenance and catastrophic failure often comes down to choosing the right repair service with proven expertise.

Professional powertrain repair requires specialized knowledge, advanced diagnostic equipment, and access to genuine parts. HMS offers comprehensive powertrain services with over fifty years of experience working specifically on Dana Spicer Clark-Hurth product lines. Our certified mechanics and high-tech workshop equipment deliver reliable repairs that keep equipment operating at peak performance.

Dana Spicer Clark-Hurth Authorized Service Excellence

Authorized service centers maintain direct relationships with manufacturers, ensuring access to genuine parts, technical updates, and specialized training. HMS operates as one of only nine officially authorized Dana Spicer service centers nationwide, providing unmatched expertise for off-highway powertrain systems.

Genuine parts availability makes the difference between quick repairs and extended downtime. Authorized service centers stock complete inventories of factory-specified components, eliminating delays from parts sourcing. Aftermarket alternatives often fail prematurely, creating repeat failures and additional costs.

Technical training from manufacturer engineers keeps service technicians current with latest diagnostic procedures and repair techniques. Dana Spicer provides ongoing education on new product lines, updated specifications, and emerging technologies. This specialized knowledge prevents misdiagnosis and improper repairs.

Factory-backed warranties protect customers from defective parts or workmanship issues. Authorized repairs include comprehensive coverage that independent shops cannot provide. Warranty protection reduces financial risk and demonstrates service quality confidence.

Comprehensive Powertrain System Coverage

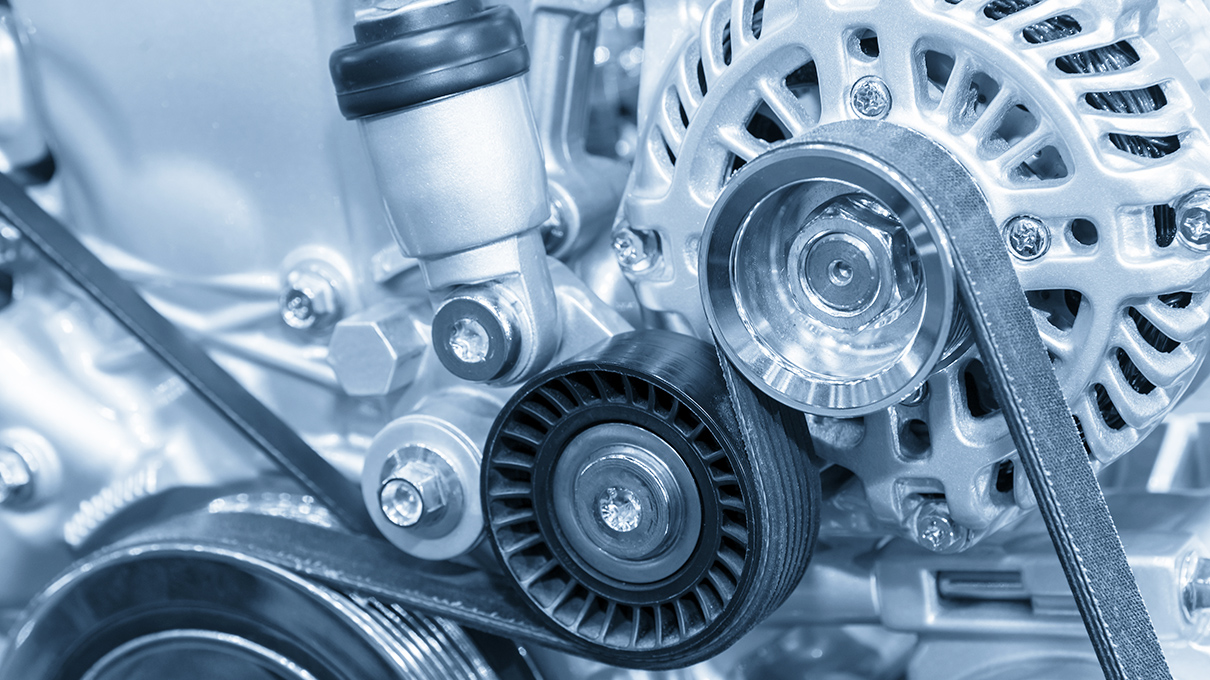

Modern industrial equipment relies on integrated powertrain systems that include transmissions, torque converters, axles, and control valves working together. Effective repair services must understand these system interactions and provide complete solutions rather than isolated component fixes.

Torque converter rebuilding restores power transfer efficiency and eliminates slipping problems. Worn friction materials, damaged internal components, and contaminated fluid create performance loss and overheating. Professional rebuilding includes complete disassembly, precision machining, and performance testing.

Transmission repair addresses complex hydraulic and mechanical systems requiring specialized knowledge. Modern transmissions incorporate electronic controls, multiple speed ranges, and precise pressure regulation. Proper diagnosis requires advanced test equipment and manufacturer-specific procedures.

Axle rebuilding encompasses differential repairs, bearing replacement, and seal renewal. Heavy-duty applications create extreme loads that wear internal components over time. Professional rebuilding includes gear inspection using specialized equipment to detect stress cracks invisible to standard visual inspection.

Control valve servicing maintains precise hydraulic system operation and prevents erratic equipment behavior. Electronic solenoids, pressure regulators, and flow control valves require clean assembly environments and calibrated test equipment. Contaminated valves create unpredictable operation and potential safety hazards.

Advanced Diagnostic Equipment and Testing

Professional powertrain diagnosis requires sophisticated test equipment that independent repair shops typically cannot afford. Specialized tools identify problems that visual inspection cannot detect, preventing unnecessary component replacement and reducing repair costs.

Equipment testing and repair services utilize advanced diagnostic procedures to pinpoint exact failure causes. Professional testing eliminates guesswork and ensures repairs address root problems rather than symptoms.

Magna Flux crack detection reveals internal stress fractures in gears and shafts that could cause catastrophic failures. This magnetic particle inspection identifies microscopic cracks that develop from cyclic loading and fatigue. Early detection prevents complete gear destruction and costly emergency repairs.

Hydraulic flow bench testing measures pump and motor performance under controlled conditions. Precise flow, pressure, and efficiency measurements determine component condition and remaining service life. Testing data guides repair decisions and validates rebuild quality.

Electronic system diagnosis requires computer interfaces and manufacturer-specific software. Modern powertrains incorporate complex electronic controls that manage shifting, pressure regulation, and system protection. Proper diagnosis prevents unnecessary electronic component replacement.

Industrial-Grade Cleaning and Inspection Processes

Proper component cleaning removes contaminants that cause premature wear and system failures. Industrial washing equipment and specialized solvents ensure complete debris removal from internal passages and precision surfaces.

Industrial-sized washing machines handle large powertrain components that smaller shops cannot accommodate. Multi-stage cleaning processes remove metal particles, carbon deposits, and fluid residues that standard cleaning cannot eliminate. Clean components prevent contamination of new seals and bearings during assembly.

Complete disassembly allows thorough inspection of all internal components before repair decisions. Partial disassembly often misses wear patterns and damage that affect system reliability. Full inspection identifies all problems during initial teardown rather than discovering additional issues during assembly.

Digital photo documentation provides detailed records of component condition and repair procedures. Visual evidence helps customers understand repair necessity and validates completed work. Photo records support warranty claims and future service planning.

Multi-Industry Application Expertise

Different industries create unique operating conditions that affect powertrain wear patterns and failure modes. Professional repair services must understand these applications to provide appropriate solutions and prevent repeat failures.

Construction equipment operates in harsh environments with extreme loads and contamination exposure. Dust, debris, and shock loading create accelerated wear that requires specialized repair approaches. Construction-specific expertise prevents premature failure in demanding applications.

Mining operations subject powertrains to continuous heavy loads and abrasive conditions. Underground environments create corrosion problems and limit maintenance access. Mining-specific knowledge addresses these unique challenges with appropriate materials and procedures.

Port operations require powertrains that handle constant loading cycles and marine environment exposure. Salt air corrosion and continuous operation create specific maintenance requirements. Port equipment expertise ensures repairs withstand these demanding conditions.

Agricultural applications involve seasonal loading patterns and field contamination exposure. Harvest season operation cannot tolerate equipment failures that delay time-sensitive activities. Agricultural expertise provides reliable repairs that perform during critical operating periods.

Fast Service Delivery for Critical Operations

Equipment downtime directly impacts productivity and profitability, making repair speed critical for operational success. Professional services must balance quick turnaround with quality workmanship to meet customer needs.

Emergency repair services provide immediate response for critical equipment failures. Production schedules often cannot accommodate standard repair timelines, requiring expedited service to minimize downtime. Emergency services include overnight parts delivery and extended service hours.

Rebuilt exchange units eliminate extended downtime by providing immediate replacement components. Exchange programs allow equipment to return to service while original components undergo complete rebuilding. This approach minimizes operational disruption and spreads repair costs over time.

Preventive maintenance scheduling reduces emergency failures and extends equipment life. Regular service intervals catch developing problems before complete failure occurs. Scheduled maintenance costs significantly less than emergency repairs and prevents production losses.

Condition monitoring for predictive maintenance enables proactive service planning based on actual component condition rather than arbitrary time intervals. Advanced monitoring techniques identify wear patterns and performance degradation before failures occur, optimizing maintenance timing and reducing unexpected downtime.

OEM Manufacturing and Custom Solutions

Original equipment manufacturers require specialized partners capable of producing custom drivetrain components and assemblies. OEM relationships demand consistent quality, engineering support, and flexible production capabilities.

Custom drivetrain design addresses unique application requirements that standard products cannot meet. Engineering expertise in power transmission systems enables development of optimized solutions for specific operating conditions. Custom designs provide competitive advantages through improved performance and reliability.

Small batch manufacturing serves niche markets and specialized applications where volume production is not economical. Flexible manufacturing capabilities accommodate varying production quantities and specification changes. Small OEM support enables innovation and market differentiation.

Quality certification ensures manufactured components meet stringent performance and reliability standards. ISO certification and manufacturer approvals validate production processes and quality control procedures. Certified quality reduces customer risk and supports warranty programs.

Hydrostatic Pump and Motor Specialization

Hydrostatic drive systems require specialized knowledge of pump and motor technologies that differ significantly from traditional powertrain components. Professional services must understand these systems to provide effective repairs and optimized performance.

Calibrated assemblies ensure optimal performance through precise adjustment of system parameters. Factory calibration procedures optimize efficiency, response, and power output for specific applications. Proper calibration maximizes equipment performance and extends component life.

Pre-tested assemblies validate performance before shipment to prevent field problems and installation delays. Comprehensive testing verifies pressure, flow, and efficiency specifications under controlled conditions. Testing documentation provides performance baselines and warranty protection.

Factory settings optimize system performance for intended applications rather than generic configurations. Application-specific adjustments account for load characteristics, duty cycles, and operating environments. Optimized settings improve productivity and reduce operating costs.

Inspection and Reporting Documentation

Comprehensive inspection procedures document component condition and identify all repair requirements before work begins. Detailed reporting helps customers understand repair necessity and make informed decisions about component replacement versus rebuilding.

Extensive inspection reports include detailed findings about wear patterns, damage assessment, and recommended repairs. Professional documentation helps customers understand component condition and repair requirements. Clear reporting builds trust and justifies repair recommendations.

Cost analysis compares repair options including rebuilding, replacement, and exchange alternatives. Detailed cost breakdowns help customers make informed decisions based on their specific operational and financial requirements. Professional analysis considers long-term reliability and total ownership costs.

Digital photography provides visual evidence of component condition and supports repair recommendations. High-resolution images document wear patterns, damage areas, and assembly procedures. Photo documentation supports warranty claims and provides service records for future reference.

Industry Standards and Compliance Resources

Professional powertrain repair services must comply with industry standards and safety regulations that govern industrial equipment operation and maintenance.

Occupational Safety and Health Administration (OSHA) provides comprehensive workplace safety standards for industrial equipment maintenance and operation. OSHA regulations ensure safe working conditions and proper procedures for equipment repair and maintenance activities.

Environmental Protection Agency (EPA) establishes environmental regulations for fluid disposal, emissions control, and workplace environmental safety. Proper compliance with EPA requirements ensures environmentally responsible repair practices and waste management procedures.

Call to Action

Don't let powertrain failures shut down your operation. Contact HMS today to schedule your comprehensive powertrain evaluation and discover why over fifty years of specialized Dana Spicer Clark-Hurth experience makes the difference in keeping your equipment running reliably.

Frequently Asked Questions

What types of powertrain systems can HMS repair and rebuild?

HMS services the complete Dana Spicer Clark-Hurth product line including torque converters, transmissions, axles, drivetrain kits and systems, and electric and manual control valves. Our expertise covers off-highway applications across construction, mining, agriculture, port operations, locomotives, and industrial drives. We also manufacture custom drivetrain components for OEMs and provide hydrostatic pump and motor rebuilding services. Our fifty years of experience with Dana products means we understand the specific requirements and common issues affecting these systems across different industries.

How long does a typical powertrain repair take at HMS?

Repair timelines depend on component complexity and parts availability, but HMS prioritizes fast service delivery to minimize equipment downtime. Standard rebuilds typically complete within one to two weeks, while emergency repairs can often be expedited with overnight parts delivery and extended service hours. Exchange unit programs provide immediate equipment replacement while original components undergo rebuilding, eliminating extended downtime. We provide detailed timeline estimates during initial inspection and keep customers informed of progress throughout the repair process.

What diagnostic equipment does HMS use to identify powertrain problems?

HMS utilizes advanced diagnostic equipment including Magna Flux crack detection systems that reveal internal stress fractures invisible to visual inspection. Our hydraulic flow bench testing measures precise pump and motor performance under controlled conditions. Electronic diagnostic computers interface with manufacturer-specific software to troubleshoot complex control systems. Industrial-grade cleaning equipment removes contaminants for thorough component inspection. This sophisticated equipment enables accurate diagnosis and prevents unnecessary component replacement while ensuring repairs address root causes rather than symptoms.

Does HMS provide warranties on rebuilt powertrain components?

As an authorized Dana Spicer service center, HMS provides comprehensive warranties backed by manufacturer support that independent shops cannot offer. Our warranties cover both parts and workmanship defects, reducing customer financial risk and demonstrating confidence in repair quality. Warranty terms vary based on component type and application requirements, but all repairs include protection against defective materials or improper workmanship. Digital documentation and photo records support warranty claims and provide detailed service history for future reference.

Can HMS handle custom drivetrain manufacturing for OEM applications?

HMS specializes in OEM partnerships with three engineers on staff capable of designing and manufacturing custom drivetrain solutions. Our engineering expertise addresses unique application requirements that standard products cannot meet, providing competitive advantages through optimized performance and reliability. We handle small batch manufacturing for niche markets and specialized applications where volume production is not economical. Quality certification ensures manufactured components meet stringent performance standards, and flexible production capabilities accommodate varying quantities and specification changes throughout the development process.